Manual of LaserDraw 1.0123C 1 Interface operation Inferface Components The follwing picture is the initial screen of the program. 40W Co2 Laser Engraving Machine Price +/- 500,- (excl. I was a Whisperer user for a while but it was cumbersome to iterate through experiments with Whisperer. MANUAL LASER ENGRAVING STARTER KIT SINGLE SPARK Your business-in-a-box SINGLE SPARK CHAPTER ONE EQUIPMENT Here you see an overview of the required equipment, including a short description. Most functions of the program can be found in the menu bar, tool bar and attribute bar. For example I often run the same job a few times to get the power settings correct, but move the objects around to cut/mark places on the same piece of test material. In Whisperer this would require updating the file in Inkscape and refreshing in Whisperer, or modifying the file, saving it under a different name, and then loading the new file in Whisperer. Inside MeerK40t one can move the objects and images around at will. So I can load a single SVG, run in on the K40 then drag the objects to a different location on the bed and run it again without editing the file externally at all. I can even save that file and the modifications made inside MeerK40t to use it later (or even edit those changes further in Inkscape).įurthermore it supports adding multiple jobs to the queue.

LASERDRW MANUAL SOFTWARE

So while the laser is still cutting the first job I can begin setup in the software on another job. If you dont like to tinker, if you are not at all mechanically inclined, or if this is a mission-critical business appliance you may want to find a US laser. Laserdrw 3 manual software upgrade#Īnd queue that up to run on the same stock inside the laser cutter and it can begin as soon as the first job completes. The tube of goo (silicone sealant) is for insulating the high voltage connections on the laser tube and nothing else. 3 years ago It´s a bit diffuse, it can be used to interpret 2 or more pixels per motor step, which will make the outcome smaller, or leave bigger gaps in engravings. These are only a few of the advancements in MeerK40t that significantly sped up my workflow. The path chosen by the laser is absurdly stupid and lasering times are absolutely astronomical.

I have not tested this enough to know exactly what it does when cutting/engraving. A 95mmx50mm surface about 1/3rd filled is taking 3-4 hours because the laser head moves up, down, and then fires a tiny burst to etch a single line. Ideally I think it would be 1000x faster if the head would just travel back and forth row by row and. It also support PPI power modulation of the laser which is simply not available in any other software with the stock controller board. More advanced rotary attachment support, tools to make material alignment easier (especially on machines with stock smoke vent), and a supports the same file conventions that work in Whisperer.

LASERDRW MANUAL DRIVER

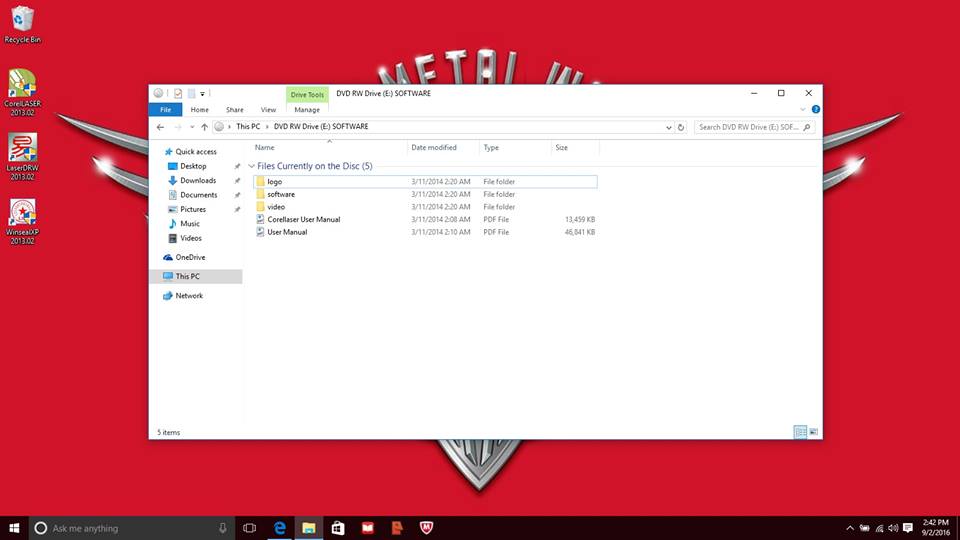

It's driving me mental, and any suggestions would be massively appreciated.As previously mentioned, it works with either driver in Windows so you can continue to use whatever other software you choose as well. I'm producing SVG files and loading them into CorelDraw12 with the supplied laser etching plugin. I've experimented a lot and I can't find a way to specify the path I want the laser to take other than "shortest path" and a few other even more inefficient options. Ideally I think it would be 1000x faster if the head would just travel back and forth row by row and etch where necessary rather than taking these stupid paths. On the CD delivered with your machine you have the software needed. The path chosen by the laser is absurdly stupid and lasering times are absolutely astronomical. Some machines arrives with a tube of silicone, this is used to isolate the connectors on the laser tube when/if you need to change it. I've gone through the learning process of actually getting things etching and they are turning out really well, except for one major frustration. I bought a cheapo chinese usb 40w laser with CorelLaser/LaserDRW software. Major newbie here - I'm creating cold storage wallets for bitcoins, laser etched on wood.

0 kommentar(er)

0 kommentar(er)